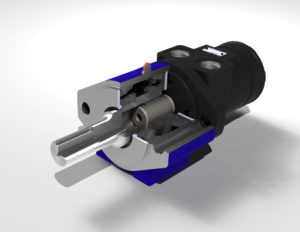

A longtime customer called us to ask if we had a solution to the premature shaft seal failure he was experiencing with his Eaton Char-Lynn H-Series hydraulic motors.

We at Stanley M. Proctor Company get a lot of calls from people with industrial automation problems. Often, solving a customer’s problem boils down to a question of figuring out how to make a machine faster, slower, more accurate, more durable, or run hotter or colder.

In this case, the challenge was to make a machine more durable to solve our customer’s vexing abrasion problem.

The Challenge

This customer is a manufacturer and packager of dry cement mix. So the shaft seals of the hydraulic motors were constantly exposed to a very abrasive airborne particulate that would readily stick to any moisture, including hydraulic oil, turning it into a thick, abrasive paste.

This paste would work its way under the lips of the shaft seals. The rotating shafts with abrasive paste would then literally sand away the soft Buna seal. Causing big problems.

Hydraulic fluid leaking onto the machinery, product and floor, creating an employee safety hazard and financial loss from damaged product.

Excessive wear-and-tear on the motors, necessitating frequent replacements, with expensive downtime and replacement costs.

If we could solve the problem of protecting the motor from the abrasive, airborne particulate, we would save the customer a lot of money and help keep the company’s employees safer.

The Solution

An unusual problem requires an ingenious solution. We suggested the customer install a…